A Code of Practice has been developed by members of the association in collaboration with specialist consultants and with the knowledge of the Environment Agency, for MIBAAA members use only.

Member companies are: Blue Phoenix, Day Aggregates and Fortis IBA.

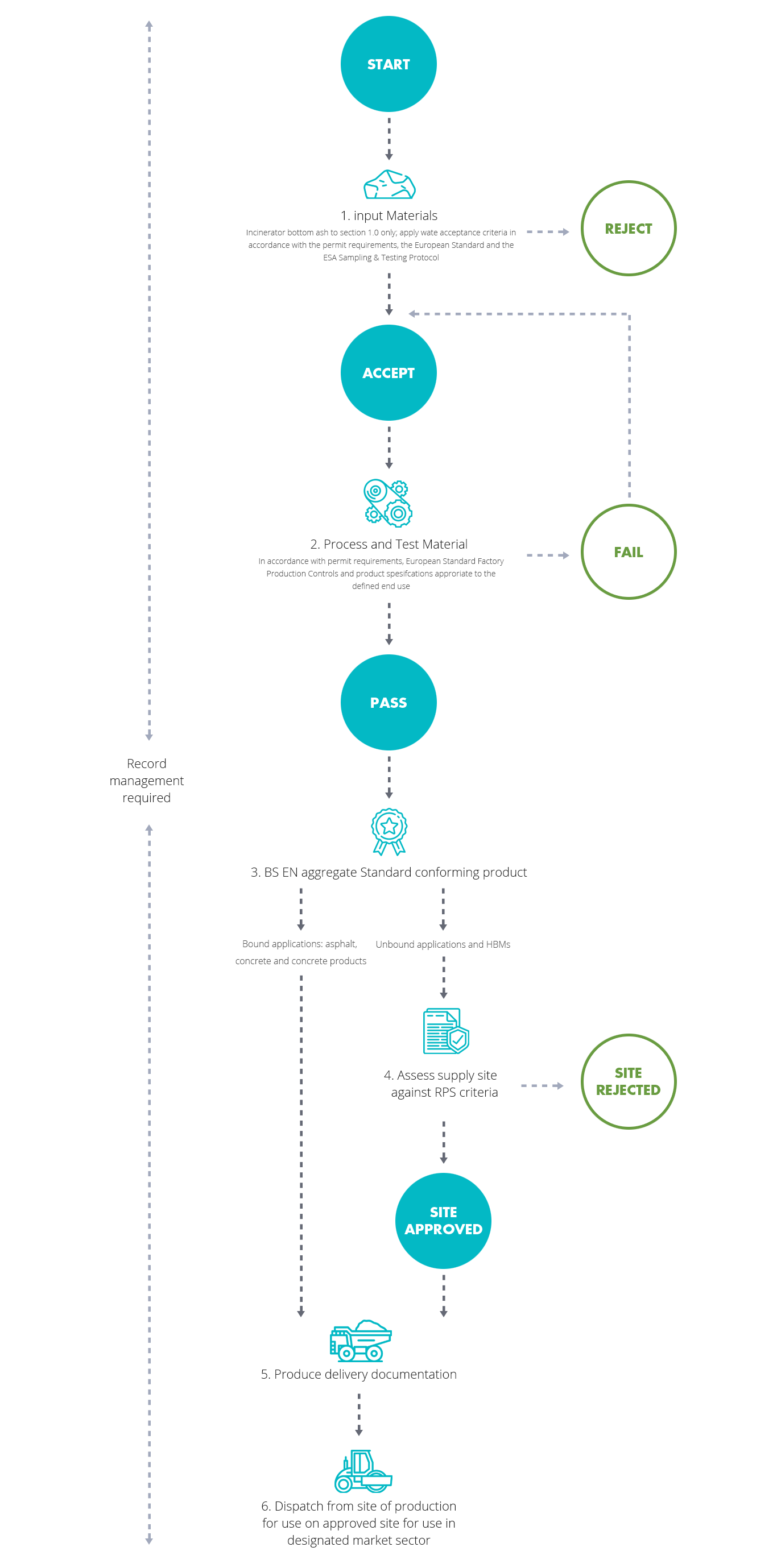

The Code of Practice ensures that IBA Aggregate is produced to harmonised and UK aggregate specifications and also ensures that our products are supplied to environmentally appropriate locations across the UK.